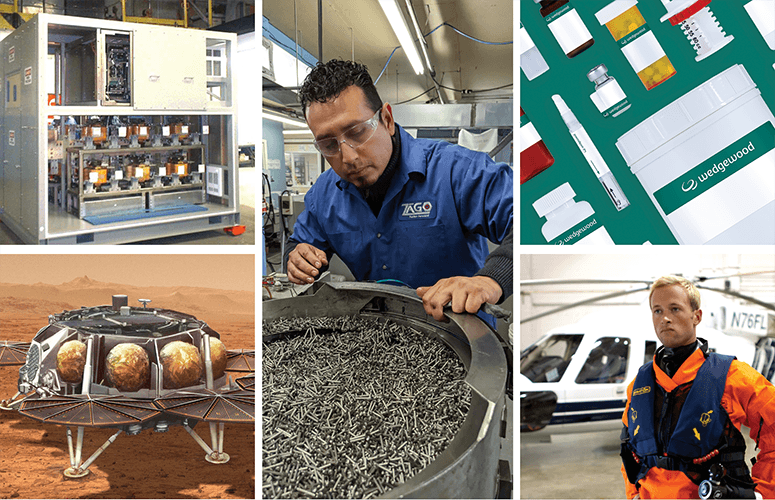

Manufacturing Roundtable: Challenges & Opportunities

A broad range of issues discussed reveals the challenging aspects of operating a manufacturing company in the Garden State.

On Mar 7, 2024The New Jersey Business & Industry Association has dubbed 2024 as the Year of the Manufacturer, honoring an industry that encompasses approximately 11,363 businesses and nearly 340,000 employees in the state. Manufacturing has played a vital role in the New Jersey’s economic development, dating back to the Industrial Revolution, and it came to the forefront during the COVID-19 pandemic, when it was labeled essential and remained open, providing the products everyone needed during the worst virus outbreak the world has seen in more than a century.

In the Q&A below, manufacturing experts in the state discuss what is needed to boost the industry as it faces increased government regulations, workforce shortages, supply chain issues, inflation, high interest rates and other challenges.

Meet our 7 Panelists

What are the top regulatory issues manufacturers are facing today?

Connolly: Dealing with red tape is one of the biggest issues. No. 1 is dealing with the New Jersey Department of Environmental Protection (NJDEP). One of our board members was adding to his facility in Essex County. It took the company three years to get all the NJDEP paperwork done. Meanwhile, he built a facility in Ohio in just four months.

Lindholm: There are a ton of regulations and rules for manufacturers to comply with. The other thing that compounds this are the fees that get lopped onto them. I don’t think other states in which we compete have all these associated fees.

Switlik: I have seen a drastic uptick in compliance necessities. It’s not that we take specific issue with what [the state] is mandating, but [keeping up] with the mandates has become a full-time job. … I’ve had to hire additional human resources staff to handle all of that.

Friedberg Rottenstrich: We started this business 30 years ago and I sometimes wonder how new entrepreneurs will start businesses like [ours] when the whole field is complicated.

Marotta: Last week, I spent a frustrating morning with folks from New Jersey Economic Development Authority (NJEDA) and Business Action Center who were really trying to help me with state and local issues related to sewer system connections. In the end, I was told that the Highlands Council would not permit a sewer extension. None of my competitors in any industrialized state are dealing with anything like that.

Bowden: Red tape for us is our biggest challenge. We work closely with the New Jersey Board of Pharmacy. We try to be proactive in communicating with them when we have a project. Last fall, we had to replace a floor, based on their recommendation, because they thought it was too slippery. We worked with them on timing and told them the steps of the entire process. We had to shut down our operating lab and we needed their approval to get back into production. We agreed to a period of about six weeks. It turned into almost four months.

What is Trenton doing right?

Switlik: We’ve had a great experience in working with the New Jersey State Trade Expansion Program (NJ STEP) because we conduct a lot of foreign business. We’ve been able to utilize grants that they were providing for foreign trade shows.

Friedberg Rottenstrich: We just finished installing all the equipment we purchased through the NJEDA’s Manufacturing Voucher Program (MVP) grant.

Lindholm: We also received an MVP grant. Our equipment is being delivered, then we’ll do the installation. That is a bright spot. I haven’t seen anything like that coming out of Trenton in my career.

Are workforce shortages still an issue?

Marotta: We have been able to attract and retain a number of skilled workers. The programs that have been getting a lot of attention and support through state government and other organizations have been great at establishing foundational skills. We hire for attitude and aptitude from that pool and then train people on job-specific traits. Where we see less success is when it’s a role where the skills are highly transferable.

Connolly: Hiring people is the biggest issue we see. Since the pandemic, people want to work from home. If you are an accountant, you can. When you’re in manufacturing, you can’t.

Bowden: We’ve tried to balance work from home. Fifty percent of our turnover are employees with less than one year in the organization. Once we get them through that first year, and have managed the expectations of what their role is, the culture of our organization makes them want to stay long term.

What workforce development programs are you taking advantage of?

Connolly: There are a lot of apprenticeship programs out there. Sometimes, we all team together, but then I think we compete against each other. I also think the county colleges are starting to compete against each other. You also have labor unions with their own apprenticeship programs. The NJEDA has its Makers and Creators program. NJBIA and NJMEP just received a grant from the New Jersey Community College Consortium for Workforce and Economic Development for apprenticeships. There is also a program where veterans are trained as they retire from the military. So, there’s a lot out there. You just have to figure out which ones work best for you.

Lindholm: One of the things that I’ve harped on is that there are so many organizations getting state dollars for training that it gets overwhelming sometimes. Also, I’m concerned that the state’s training dollars are getting watered down by so many different organizations trying to get their own specific programs. Couldn’t we get a better bang for the buck if there was some way to pool all those resources more efficiently?

Siekerka: Focus NJ has created a Workforce Development Initiatives and Opportunities Resource website where anybody can input the types of [training] programs available so people can find where they are. For example, if you search for welding, you may find free programs that provide that training. We also have a grant to take that to the next level. That’s a big part of what we’re trying to do to get all of this in one space.

We also are involved in the New Jersey Manufacturing Skills Initiative, a statewide manufacturing training program funded by the New Jersey Department of Labor and Workforce Development (NJDOL) and granted to the consortium. The goal is to establish a comprehensively structured approach to manufacturing workforce development that responds to manufacturers’ needs, while, at the same time, provide education, training, and career opportunities. The initiative will serve as a statewide repository and ambassador for all manufacturing-related education and training. As part of the initiative, NJBIA and NJMEP are going to try to have employers match and hire individuals coming out of training programs. The goal is to employ 125 skilled workers over the next 18 months.

Because of global supply chain issues, have you seen examples of manufacturing reshoring?

Connolly: It’s happening, but it’s slow. I’m not sure we’ve seen much in New Jersey yet, but talking to other National Institute of Standards and Technology (NIST) MEP centers, they’re starting to see some of that. There’s a lot of money in the CHIPS Act. So that will help. I think people and Wall Street have learned that we can’t outsource everything. We need to make things back home.

What keeps all of you in New Jersey?

Lindholm: Speaking for Falstrom Company, we’ve been here for a long time (153 years). So, that’s part of the reason. Also, we can’t discount the large population that we have in New Jersey that benefits manufacturing and industry in general. The diversity of our population is also key. That helps make manufacturing and other businesses stronger. We also have highly skilled employees that you might not be able to find in rural Ohio or Wisconsin.

Bowden: We definitely have the ability to find talent here. We have a site in Ohio where we’re struggling to find good talented people.

Marotta: We’ve added more than 300 highly skilled workers over the last two years, and we’ve been successful in hiring people from Northern New Jersey, Southern New York, and Eastern Pennsylvania. Outside of these three specific geographies, and the other 47 states, we have no traction in being able to bring somebody else here. We might be forced to tap into a new labor pool in the future. That’s not something we want to do, but if we have to – unless New Jersey becomes more competitive overall and attracts workers from other states – we’ll have to follow the labor.

Siekerka: We are hearing from large companies that they are not able to bring workers from other states to New Jersey. People will not relocate here because of our high cost of living.

How have you coped with high interest rates and inflation?

Friedberg Rottenstrich: High interest rates have been a consideration in terms of how we finance expansion. Inflation seems to be coming down, but we’ve had to take a hard look at our expenses.

Marotta: Optional projects were scaled back or paused because of financing.

What is your take on the economy for 2024?

Siekerka: Based on NJBIA’s Business Outlook Survey, businesses went from being cautiously pessimistic in 2023 to being cautiously optimistic in 2024.

Switlik: I don’t think it’s going to be as bad as everyone has talked about, but it’s not going to be super cushy for us, either.

Connolly: I agree with Sarah. Our customers are moderately optimistic, versus last year.

To access more business news, visit NJB News Now.